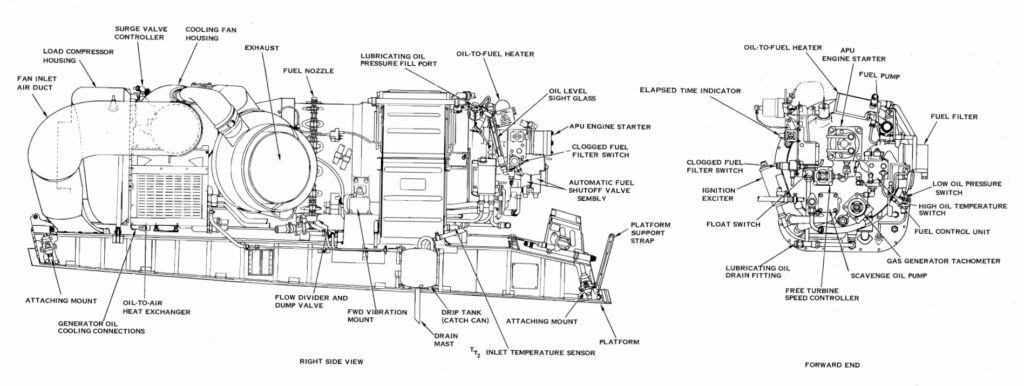

Tristar (L1011) Auxiliary Power Unit

ST6L-

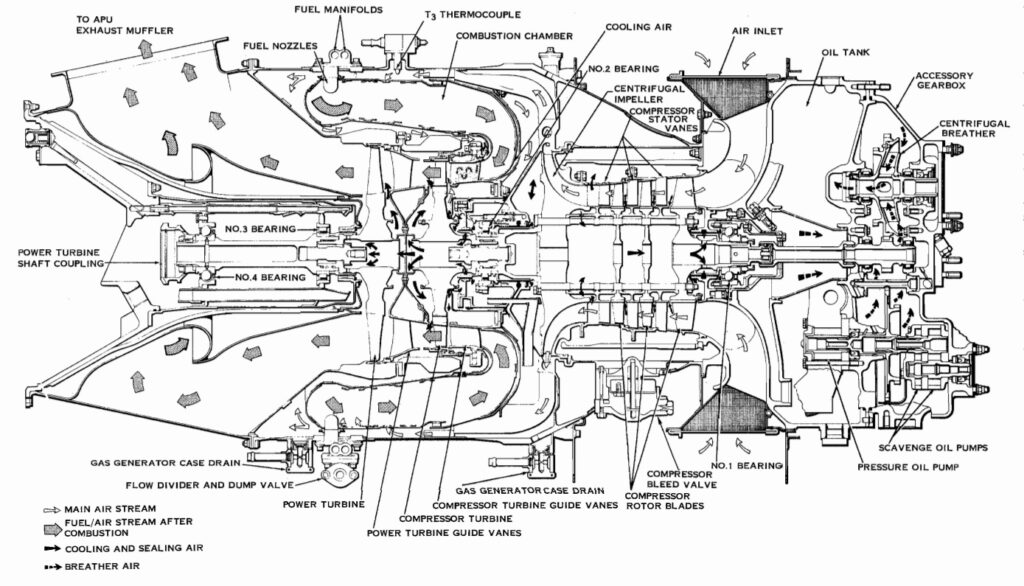

The ST6L-

The two-

The ST6 fuel system consists of a re-

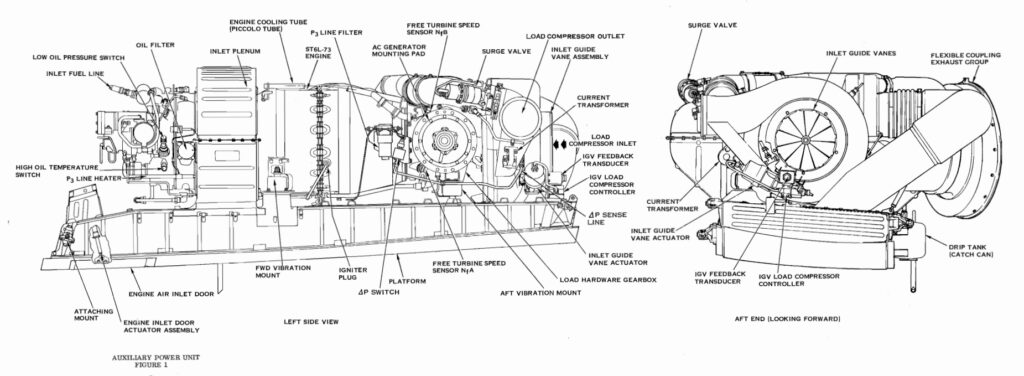

The engine load compressor and alternator must be driven at constant speed and so a governing system is fitted to the engine. This consists of an electronic system fed with speed and temperature sensors mounted in the engine. A special electrical spill valve is connected to the air control circuit in the fuel system and is driven with a signal from the electronics. A control loop is formed that keeps the turbine speed constant, regardless of electrical or compressed air loads. Additional protection and safety circuits are also built in to the electronics as is the aircraft cock-

A second electronic control loop is also used to control the airflow in to the load compressor. A pneumatic actuator alters the angle of a set of guide vanes that are mounted in the load compressor intake. Bleed air from the main engine compressor provides the force to move the actuator and a second electrically operated air spill valve regulates the position of the vanes in conjunction with electronic control system. Feedback of the vane position is provided by a potentiometer sensor mounted with the actuator mechanism.

A condition occurs for main engine starting where the vanes are fully open and the system runs at maximum capacity (max mode) to provide the greatest possible air flow. To crank the RB211 to starting speed requires some 500 or so “air horsepower” to be delivered from the APU.

The pictures below illustrate how the APU was derived from the PT6 turbo-prop engine and the similarities of the front end of the engine can be seen.

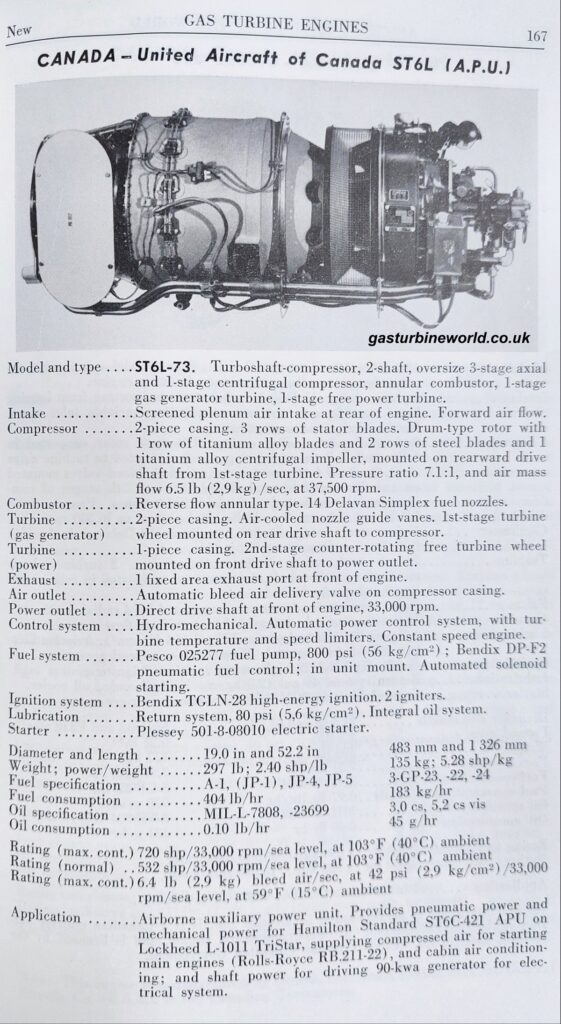

ST6L-73 Specification/Characteristics

Power Output...........….……………………………......................................................……………………….………….…………...635 Hp

RPM..............….………………………………………..........................................…….................NG 37,000 rpm, NF 33,000 rpm

Compressor…………………………..........……...........................................…..……….…3 stage axial followed by 1 stage radial Compressor……..………….......………………….........................................…………..…….single stage radial with variable IGVs

Load Compressor Air Mass Flow..…….........................................…………..……….385 Lbs/Min @ 41 PSI (Inc 45Kw)

Overall Pressure Ratio..…………...….........................................…............….………………………………………………………..….7:1

Combustion Chamber..……………............................................…......Reverse Flow Annular with 14 Duplex Burners

Compressor Turbine..….……………............................................……………………………………………….....1 Stage Axial each

Power Turbine..………….............…………….............................................…………………..........1 Stage Axial with reduction gearboxLayout..................................................................……………………..….......Two Spool with Accessory Gearboxes Starting................….…………….............................................…………………………………………………….........Starter Generator

Ignition......….………………………................................................….………...............Two Igniters with High Energy Plugs

Fuel System...................................Gear pump with Hydro-mechanical and Spill-Valve Electronic Fuel Controls,

electronic Protection System.

Oil System...............Return System with Pressure and Scavenge pumps, Engine Mounted Tank and Oil cooler

Weight.............................................................….………………………………………………………………………….................800 Lbs

Applications.............................................….……………………………………………….………………...........APU L1011 Airliner

derived from PT6 fitted to helicopters and aeroplanes