Rover Gas Turbines

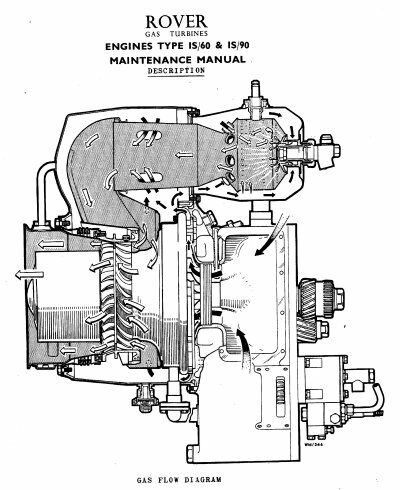

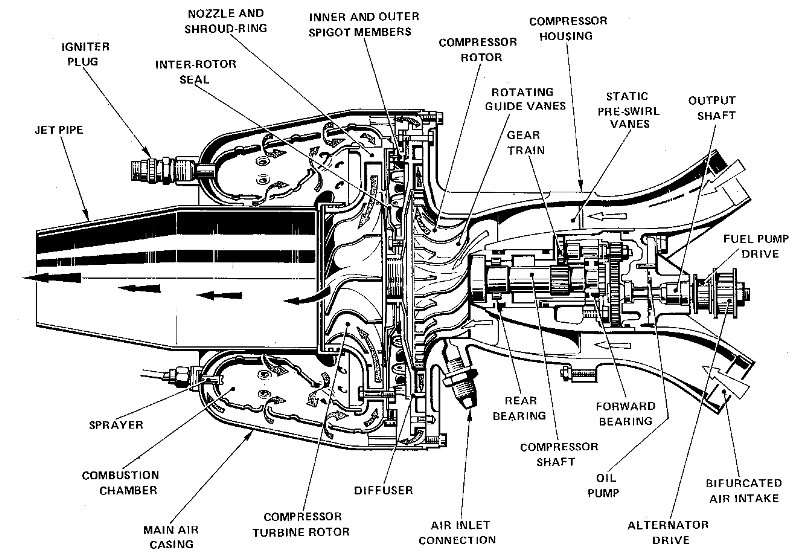

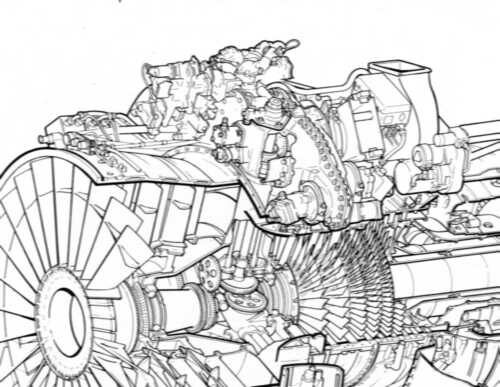

The Rover 1S60 series gas turbine engine is a small single shaft unit developing up to 90 HP. The single shaft designation describes how mechanical power is obtained from the engine. In the case of a single shaft layout, the same shaft that drives the compressor also drives a mechanical load.

The 1S60 engine is principally an industrial engine for ground use however a number of auxiliary power units (APU) or airborne auxiliary power plants AAPPs were developed from it.

The 1S60 series engine started life as the gas generator component of a twin shaft design (power take off is supplied from a mechanically free second shaft carrying a power turbine disc). The twin shaft design was developed for use in a car, the output shaft being coupled to the road wheels and torque was able to be supplied over a wide operating range starting from stationary.

The 1S60 designation depicts the specification of “One Shaft” and “Sixty Horsepower”. A later variant was able to supply of to 90HP.

The industrial units may be considered as one of the most successful small British gas turbine engines ever produced. Applications included University Instructional sets with dynamometers, aircraft ground power generator units, ship borne fire fighting pumps and auxiliary generators on hovercraft. Power take off shaft speeds of 3000, 3600 and 8000 were available as different options. Also hand-crank or electric start versions were available. Compressor bleed air was also an option.

The airborne units were fitted to the Vulcan B2 Bomber as the AAPP MK 10301 and also as the AAPP MK10201 Argosy transport turbo-prop. In the case of the Vulcan the AAPP was used to supply 400Hz electrical power and bleed air for air conditioning services. In the Argosy the AAPP supplied hydraulic power to enable doors and ramps to be operated when the main engines are stationary.

Output....................................................….………………………………………......................60 Bhp

RPM...............................................….………………………………………..............................46,000

Compressor.........................................….………………….........................Centrifugal Impeller

Combustion Chamber...............Reverse Flow Single Can with Simplex Burner Nozzle

Turbine..........................................................….…………………………………................Axial Flow

Layout...............................................….…….................Single Spool with Reduction Gear

Ignition..................................High Energy Ignitor Plug with Air/Fuel Emulsion Pump

Starting....................................................……...............Electric, Hand Crank or Cartridge

Lubrication................Wet Sump with Pressure Pump, Air or Water Cooled Oil Cooler

Fuel System.........Piston Pump with Centrifugal Governor and Temperature Limiter

Accessories……………..…………...............……..400Hz Generator, DC Generator, Hydraulic

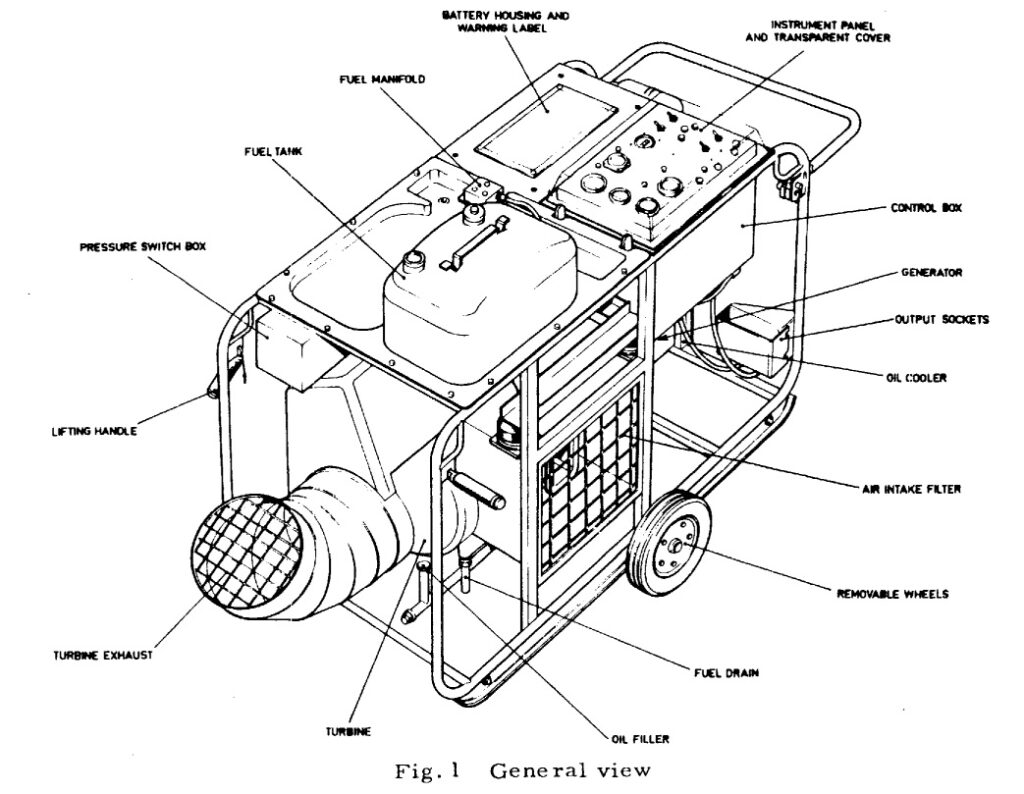

Lucas Aerospace produced a generator set for the UK MOD. A Rover 1S60 gas turbine was used to drive a 28V DC generator made by it's sister company Rotax. The generator was driven at 8,000 rpm and could produce up to 500A continuous power and 1000A peak power. The set was trolley mounted and could be "air transported" as required. The generator set itself was started by an on-board Ni-Cad battery which of course should be kept charged.

A similar unit was also built and driven by a MTU 6012 gas turbine again coupled to the same Rotax DC generator.

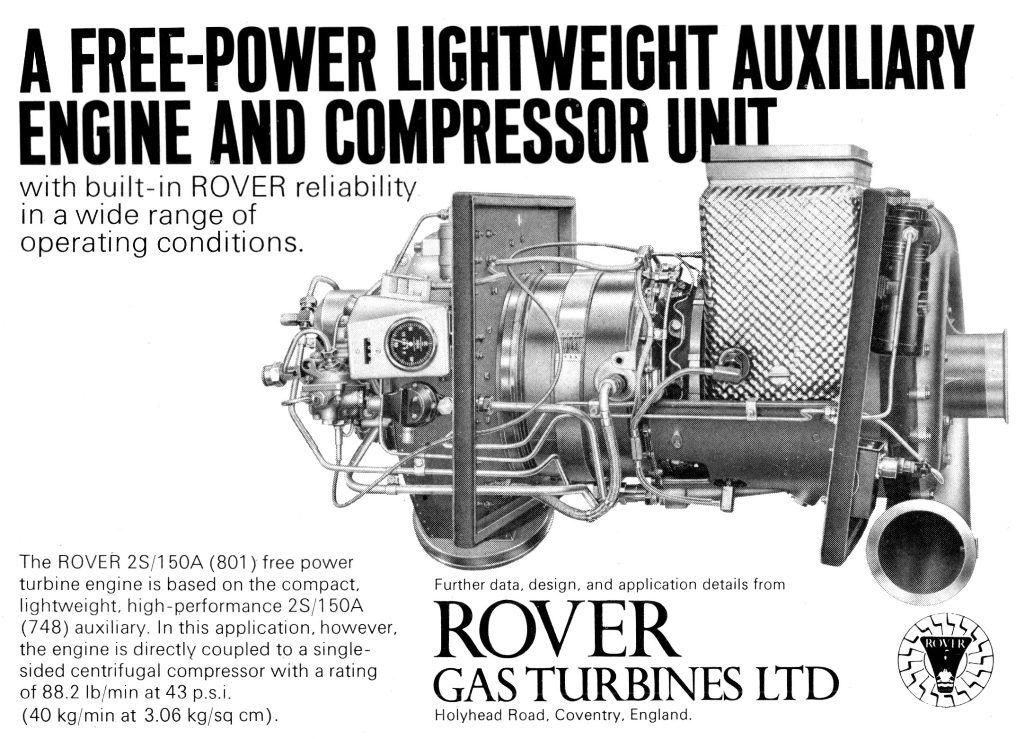

Rover 2S150 twin shaft gas turbine

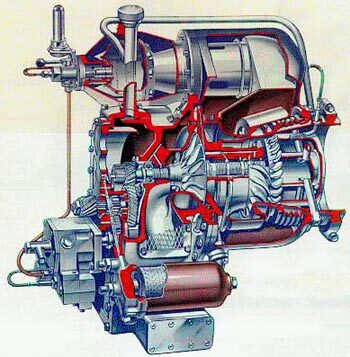

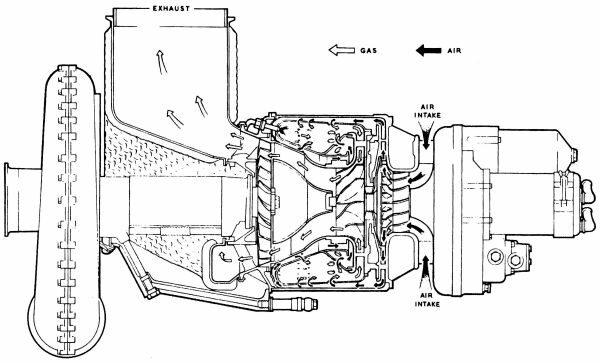

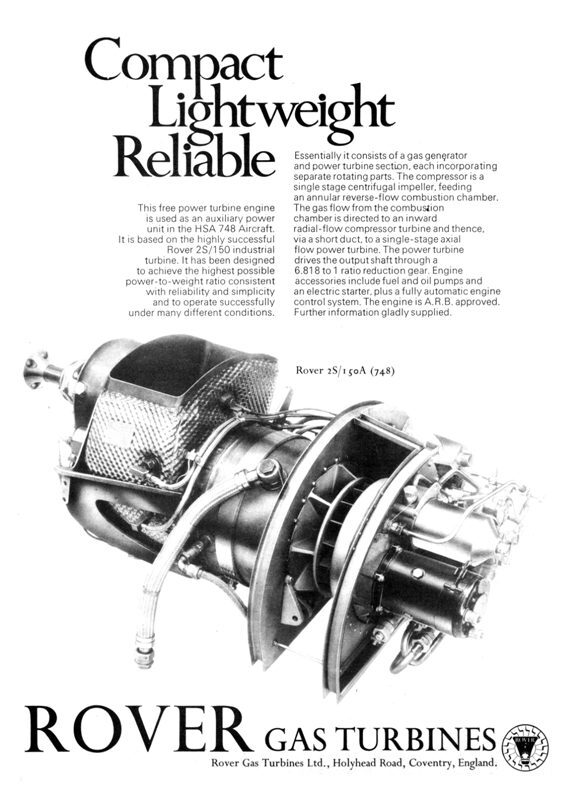

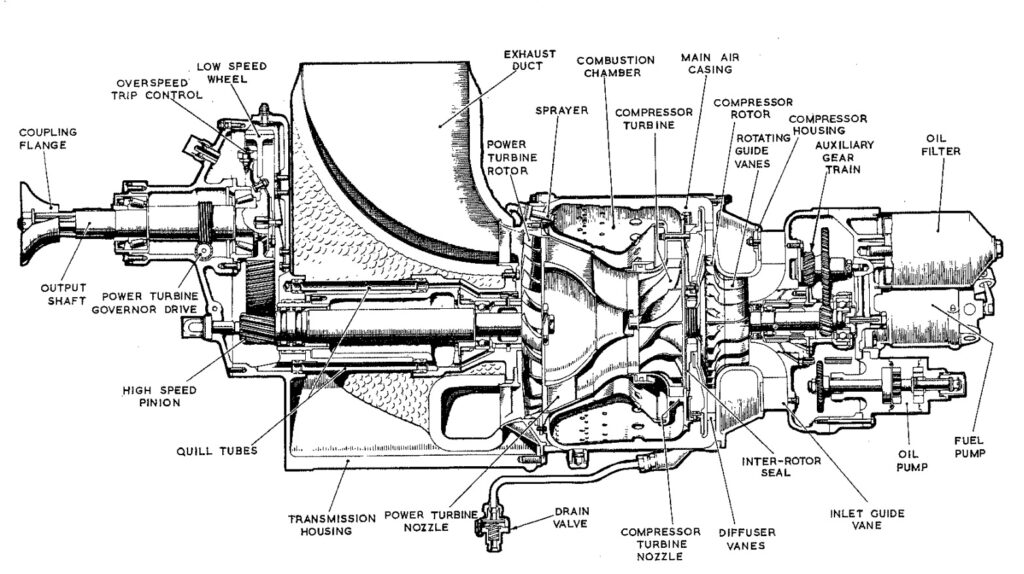

The Rover 2S100 series gas turbine engine. The engine is a two shaft design incorporating a free power turbine. The engine is derived from a second generation car engine developed for the P6 car and LeMans BRM car. The rotating core differs significantly from the 1S60 series units and consists of an overhung back to back configuration. The engine is unusual in incorporating both a radial inflow compressor turbine and an axial exhaust turbine.

The automotive and motor sport versions were often fitted with a heat exchanger recuperator to improve fuel efficiency. Also automotive units featured a singe can combustor similar to the 1S60 design. Airborne units were fitted with a reverse flow annular combustor perhaps for an overall more compact layout.

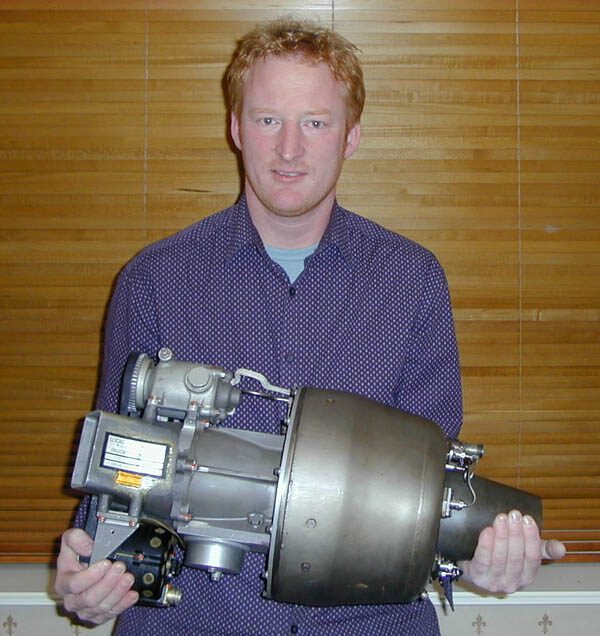

Two airborne versions also exist the Mk10401 Hawkasiddley 748 APU and the Mk10501 Nimrod APU. The airborne units adopted a reverse flow radial combustor.

The MK10401 APU was used via a shaft drive connected to an accessory gearbox to provide cabin services when on the ground.

The MK10501 APU directly drove a centrifugal compressor (originally from a 1S60 engine) to provide starting air for the main aircraft propulsion engines.

Rover AAPP MK10401 twin shaft engine (HS748 APU)

Rover AAPP Mk10501 twin shaft engine (Nimrod APU)

Rover 2S150 Specification

Power Output...............................................................................….………………………………………………………...........100-150 Bhp

Compressor RPM........................................................….……………………………………………………………………........................64,000

Power Turbine RPM............................................................….……………………………………………………………………................47,000

Compressor.............................................................................….…………………………………………....................Centrifugal Impeller

Combustion Chamber.......Reverse Flow Annular with Six Sprayer type Burners (Single Can in Automotive Versions)

Compressor Turbine........................................................................….………………………………………..........Radial Inflow Impeller

Power Turbine......................................................................................….………………………………………………………….......Axial Flow

Layout......................................................Twin Shaft, Over Hung Gas Generator with Reduction Gearbox or Compressor

Starter.....................................................................................................….………………………………………………….......Electric Motor

Ignition................................................................….…………....High Energy Ignitor with Air Pump for Burners (MK10501)

Fuel System.......................................................Piston Fuel Pump with Centrifugal Governors and Temperature Control

Lubrication...............................................................Return system with pressure and scavenge pumps, external oil tank.

Oil Spec...........................................................................................................................................OX38, 0149, Aeroshell 750.

Applications..............................MK10501 Air Compressor in Nimrod Aircraft, MK10401 Accessory Drive in HS748

Rover BRM Le Mans Sports Car, Rover P6 Turbine Saloon (Fitted with Heat Exchangers), Motor Boat Engine. Gas Generator for CT3201 Turbojet engine.

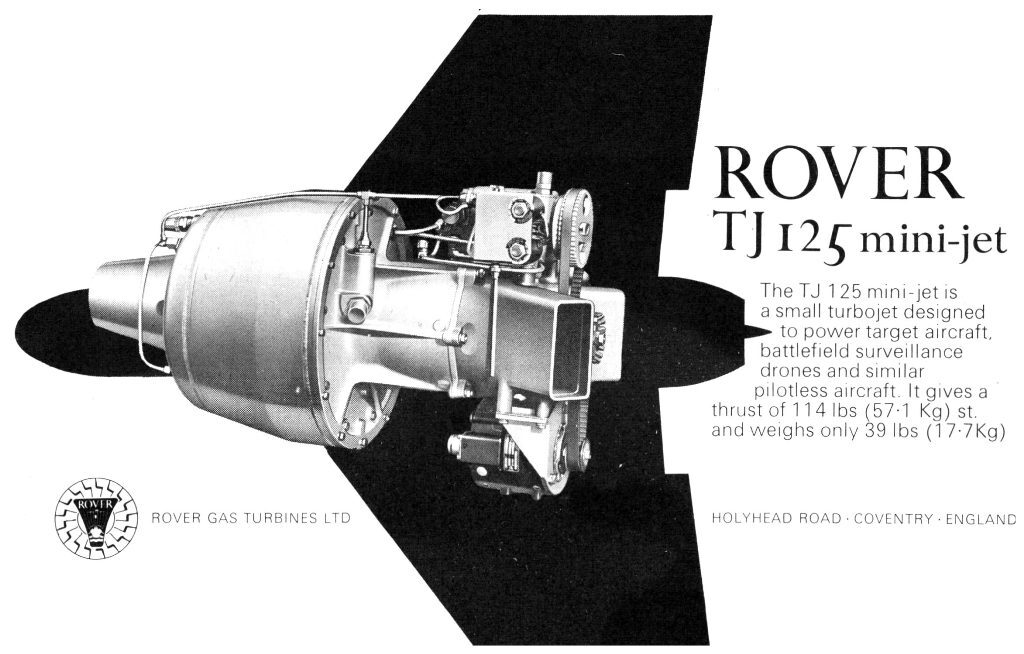

Rover CT3201 turbojet engine

The rotating core from the 2S100 series engines spawned a turbojet engine the CT3201 or TJ125. The gas generator section of the 2S series combined with a re-worked and simplified fuel and oil systems. The engine is fitted with a propelling nozzle and makes up to 125Lbs thrust at 65,000 rpm.

The CT3201 was fitted to the Belgium built Epervier reconnaissance drone. The drone was launched from a special rocket assisted launcher and could fly for up to 40 minutes and would then descend to earth with the assistance of an on-board parachute.

A great little engine and ideal for fitment to a go-kart chassis. Modest but fun performance could be had from the engine when fitted to a light weight chassis.

TJ125/CT3201 Specification

Power Output.......................….………………………………………………............114 LBs Thrust Static

RPM..........................................................65,000 rpm Take Off (100%), Cruise 57,000 rpm

Compressor.......................….…………………………...................Single Stage Centrifugal Impeller

Air Mass Flow.............….…………………………………………………………………....................0.93 kg/sec

Pressure Ratio...........….……………………………………………………………………………........................3.9

Combustion Chamber....….……....................Reverse Flow Annular with Six Fuel Sprayers

Turbine..........................….…...…………………………………....................Single Stage Radial Inflow

Layout..........................….…..………………...................Single Spool Turbojet, Overhung Rotor

Starting.........................….….…………………………………………………....................Air Impingement

Ignition......................................….……..........High Energy Ignitor Plug + Fuel/Air Emulsion

Fuel System........................….………...........Rover piston Pump with Centrifugal Governors

Lubrication.............................….……………………...........Gear Oil Pump, Integral Oil reservoir

Oil Spec..................................….………………………………………………………………………….........0-148

Accessories...............................….……………………………….......Belt Driven 26V 20A Alternator

Weight......................................….………………………………………………………………………............22 kg

Applications...........................….………...................Epervier Reconnaissance drone, Go Kart

Fuel Consumption................….………………………………………………..............1.45kg/kg thrust/hr

Dimensions Inc Jetpipe.............….……………………………………………………….........24" x 11" x 12"

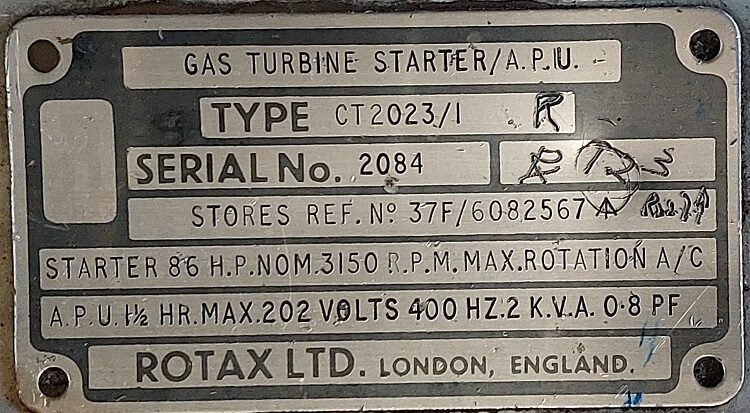

Rotax (Lucas Aerospace) CT2023 Harrier aircraft gas turbine starter/auxiliary power unit (GTS/APU)

The Rover twin shaft 2S series engines were also developed in to the starter engine for the Pegasus turbo fan engine that powered the legendary VTOL Harrier aircraft. A down-scaled unit formed a miniature twin turbo-shaft engine that was used as both an APU (on the ground) and a starter known as a Gas Turbine Starter (GTS). In APU mode the CT2023 drove a small 400Hz generator rated at just 2Kva. In GTS mode the unit produced some 75hp to rapidly spool up and start a Pegasus engine.

The CT2023 twin shaft unit was coupled to the Pegasus HP shaft via a reduction gearbox and overrunning clutch. The power in GTS mode was developed form the free power turbine. In APU mode power was developed by the gas generator, the electrical generator was driven together with the gas turbine auxiliaries (APU auxiliaries). This meant when in APU mode the power take off was still unnecessarily driven and the Pegasus HP spool would tend to rotate. To prevent this the power take off was locked and released only when start GTS mode was required. When in APU mode the APU would run at slower speed than in GTS mode and hence the unit was fitted with two governors.

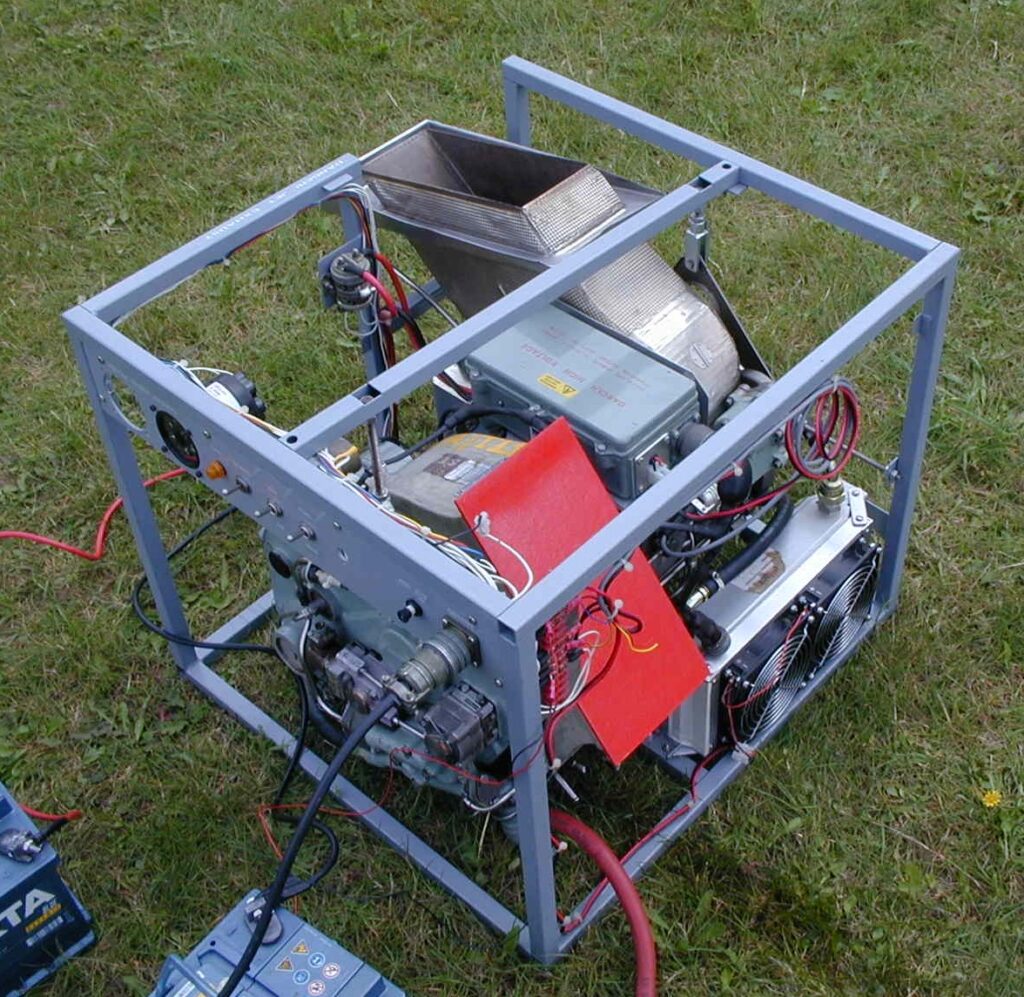

Unique CT2023 gas turbine powered race car built by Northampton engineer Roger Marmion. A twin shaft (free power turbine) configured gas turbine engine from the Harrier aircraft.