Microturbo Gas Turbines

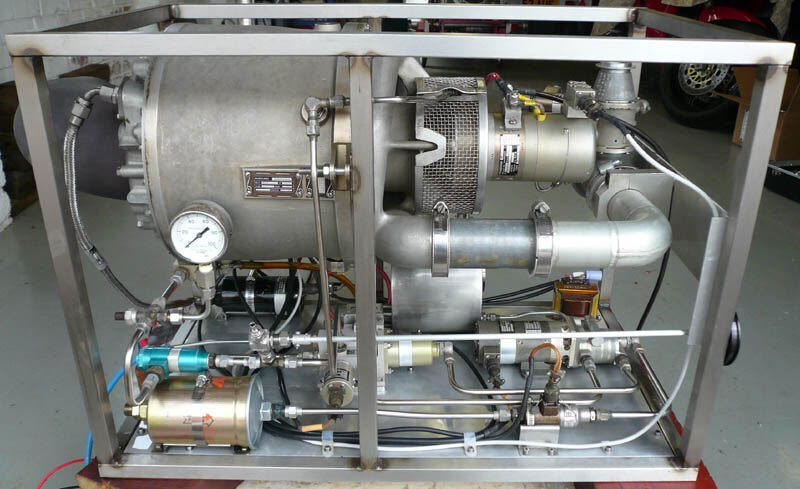

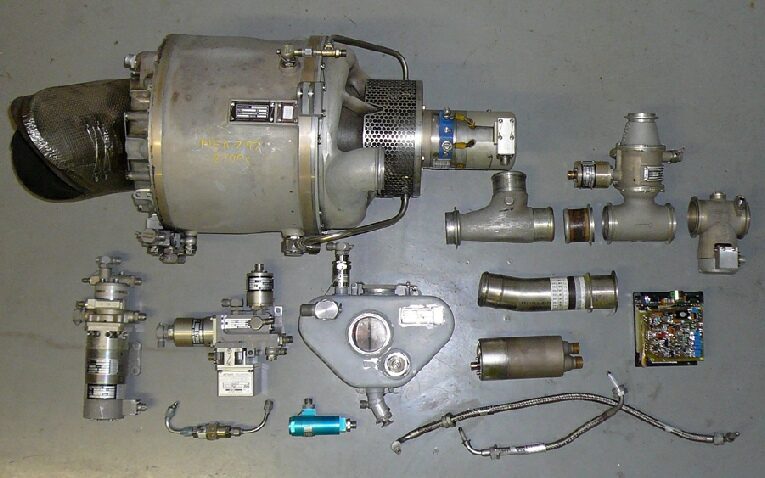

The Microturbo Saphir series auxiliary power unit. Known as an “air producer” this small gas turbine compressor unit is used to supply air for engine starting engines in many aircraft including the Jaguar and the Hawk. Other versions are available driving generators and hydraulic pumps. An early example of an electronically controlled gas turbine engine. The engine comes separated form from most of the accessories, an externally mounted electric motor driven pump is used to supply fuel and oil to the engine. A special valve in conjunction with an electronic module regulates the fuel flow to the engine and keeps it at a constant speed.

The Microturbo Saphir APU engine adopts a common compact layout. A single over-size centrifugal compressor feeds a wrap around reverse flow combustor with 8 simplex burners. Air is bled from the compressor around the diffuser by a scroll type duct. Air is split in the duct some of which passes to the combustor and some passes out two a bleed port. The compressor is driven by a two stage axial turbine and connected by a shaft supported by spring pre-loaded angular ball races. The spring ensures constant pre-load pressure and allows for thermal expansion of the bearing carrier and shaft.

On many marks of engine typically the shaft drives through a simple reduction gearbox that couples an electric starter motor permanently to the shaft. The 007 Jaguar and 047 Hawk variants are only required for main engine starting as a temporary short-duration air producer and so its acceptable to continuously drive the starter. Other models of Saphir may be used to drive DC starter-generators and additional AC alternators that are also continuously coupled.

The fuel system comprises of a 24V DC electric motor driven gear pump. The pump pressurises a fuel circuit via a pressure and flow regulator, the fuel then passes to the eight spill-type atomising burners through a manifold built in to the back of the combustion chamber casing. A second manifold returns spilled fuel from the burners back to a special electronically controlled valve. The valve is a type known as a hydraulic servo valve and uses a tiny current to augment a controlling valve using hydraulic force developed by the fuel pressure. Fuel flow (spill rate) and hence engine speed is controlled with the servo valve that is excited by an electronic control unit. A speed signal developed by a probe built in to the starter motor is processed by the electronic control unit and passed to the servo valve.

Some versions of Saphir use an engine driven oil pump to circulate oil two the engine and gearbox bearings, other versions use the same motor as the fuel pump to also drive an oil pump.

Due to the behaviour of the over-size compressor a valve arrangement is needed to manage the discharge of bleed air and prevent the compressor from surging or stalling. For this reason it’s not easy to convert a Saphir air producer in to a thrust engine. The flow matching of the compressor and turbine nozzles is incorrect.

A very successful engine the Saphir that began life in the mid 1960s, it has been made under licence by the CZ company PBS who have developed it in to a turbojet, turboshaft and turbo prop unit developing up to 200HP. The light aviation world have been looking for a small sub 300HP power unit and here it is!

Many Saphir units have been produced, the Jaguar aircraft are now retired in the UK so some Saphir units are available on the surplus market.

Microturbo Saphir Specification

Power Output......................................................................................50 BHP (Air delivery)

RPM............................................................................51,275 (100%) Idle 44,350 (86.5%)

Compressor............................................................................................Centrifugal Impeller

Combustion Chamber.............................................Reverse Flow Annular with 8 Burners

Turbine......................................................................................................2 Stage Axial Flow

Layout.......................................................................Single Spool with Reduction Gearbox

Starting..............................................................Starter Motor with Integral Speed Sensor

Ignition.............................................................................................HT Igniters with 2 Plugs

Fuel System.............Electric Motor Driven Gear Pump with Electronic Control System

Lubrication........................Dry Sump with Electric Driven Pump, Oil Spec MIl-L-7808

Air delivery.........................................................................................0.415 Kg/Sec @ 45 PSI

Application...........................................Air Producer in BAE Hawk (047), Ditto Jaguar(007), L39, Various French Aircraft