Gas Turbine Projects and Builds

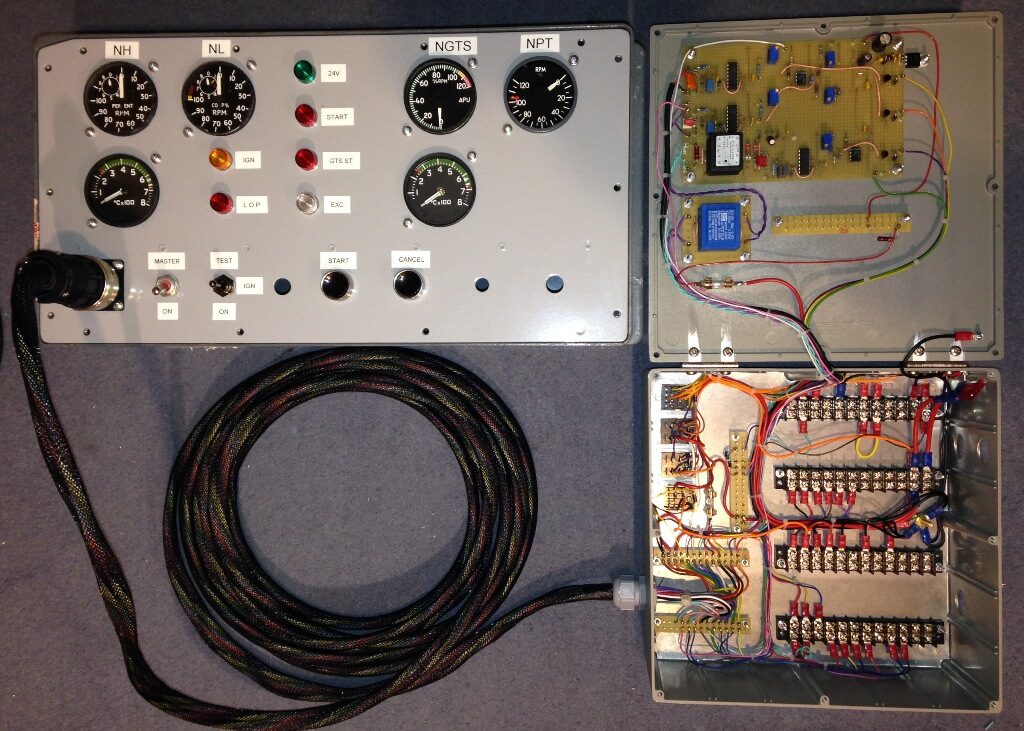

RR Adour starting and instrumentation system. A complete turn-

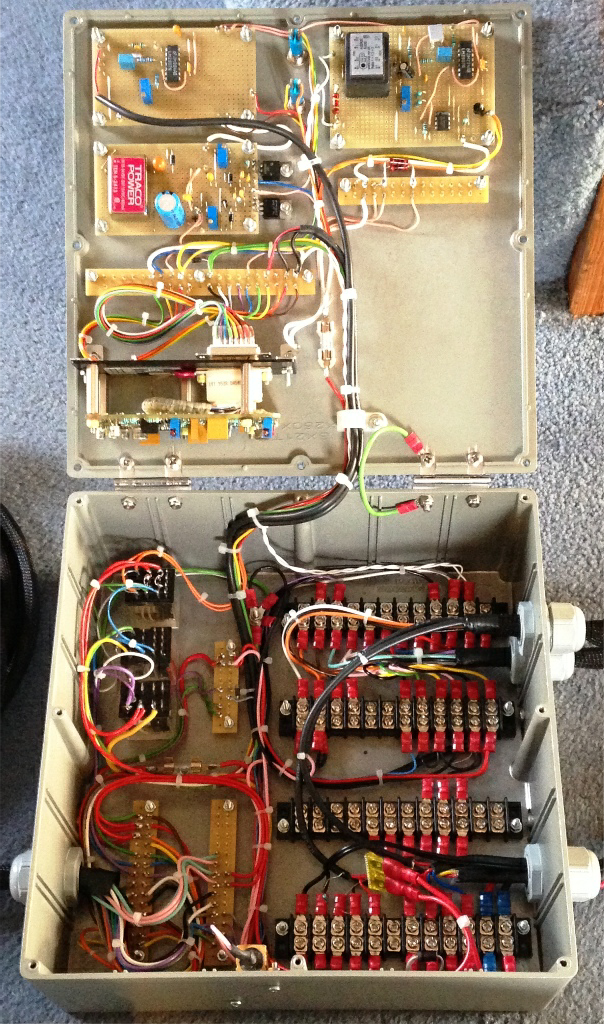

Low cost solid state ignition exciter

Low-cost ignition exciter unit for automotive microturbine A solid state inverter based capacitive discharge high energy exciter unit. The unit utilises SCR switching that replaces expensive gapped discharge systems and utilises easily obtainable electronic components. A special switchable dual energy unit producing 1 or 2 joule sparks.

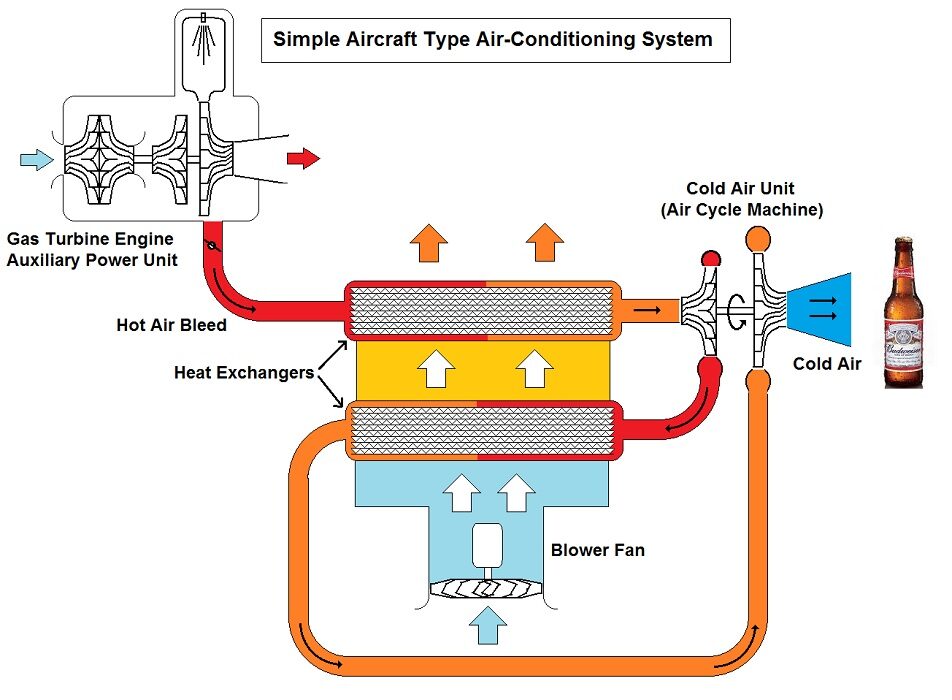

Air cycle machine beer cooler

Aircraft ACM ECS PAC jet powered beer cooler A beer refrigeration unit built from the components of an aircraft air conditioning system. At the heart of the system a special “Cold Air Unit” air-cycle machine that uses the expansion of air in a turbine to lower the temperature below freezing! The air cycle machine a common type of unit that may be obtained on the surplus market. The system is powered with air from a running APU with the addition of some inter-coolers and electrical blowers.

The cooling system: Two automotive inter-cooler units are used as heat exchangers to carry the pressurised air from the APU. A 500W 28V DC fan blows air through the inter-coolers. High pressure automotive silicone hoses feed the air to and from the CAU.

System Diagram: Hot pressurised air (180 degrees C and 38 PSI) is provided by a gas turbine engine. The gas turbine engine features an over-size compressor and is able to provide an air feed by bleeding it off before the combustion process. The engine an APU (Auxiliary Power Unit) normally resides in the rear of a commercial aircraft and is run on the ground for this purpose and to provide electrical power. The APU is also used to start the aircraft engines, during this phase the bleed air supply to the air-conditioning is temporarily shut off and diverted to the engines in order to drive the starters. In flight the main engines provide the bleed air to operate the air conditioning and pressurise the cabin. Also in flight ram-air cooling cools the heat exchnagers.

Bleed air from the APU first enters a heat exchanger that cools it using atmospheric air that is blown through it with an electric fan. The heat exchanger is in tandem with a second unit and receives the cooling air from it. The cooled air then enters a small centrifugal compressor unit that raises the pressure further. Due to this additional compression the air again becomes hot and is cooled in the second heat exchanger that is receiving cooling air from the fan. The re-cooled air now enters a radial inflow turbine unit that is driving the centrifugal compressor. The air expands in the turbine and the temperature drops to around freezing point and is exhausted to atmosphere in a cold state. Significant “mechanical work” takes place in the turbine that is required to drive the compressor and so the air looses it’s energy that was in the form of heat and pressure. The special unit that incorporates the compressor and expansion turbine is known as a “Cold Air Unit” CAU or “Air Cycle Machine” ACM.

The air exiting the system was originally drawn in to the gas turbine and heated by it’s compressor, the air now emerges colder than it went in! Water vapour contained in the atmosphere condenses out in he expanding exhaust and forms fog.

Syngas fired gas turbine

A gas fired auxiliary power unit conversion. A standard liquid fuel burning auxiliary power unit (APU) was converted for running on hydrogen rich syngas fuel. An alternative combustion system was installed with an electronic governing system and instrumentation installed also.

RR Gnome ground running rig

RR Gnome (T58) accessory and PTO refit. A pair of vintage Gnome H1000 helicopter engines, re-assembled from gas generator module, free turbine and PTO module, missing parts identified and re-fitted. The engine then instrumented and tested.

Microturbo Saphir APU ground running test bench

Microturbo Saphir Test Rig Refurbishment. The Microturbo 007 and 047 series (Hawk and Jaguar) bay servicing test bench including electronic control system, starting system and instrumentation.

Bespoke instrument panels for gas turbine engines

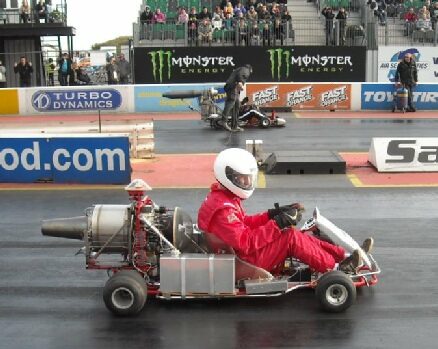

Jet powered go-kart with NPT301 turbojet

Noel Penny Turbines 301 turbo jet powered go-kart. Max thrust 315 Lbs, top speed 120 mph. The NPT301 returns great performance when fitted to a light-weight go-kart chassis. Very few engines exist in this thrust class. A fantastic experience to drive a jet-powered go-kart! The NPT301 a simple air-impingement started turbo-jet not unlike a large “model” type engine. Up to two diving tanks are needed for a cool reliable start. The engine here was one of a pair originally fitted to the LMC Leopard Jet - it has history! More here.

Jet powered go-kart with Lucas/Rotax Ct3201 turbojet

Lucas CT3201 jet powered go-

Capstone microturbine rig for University testing lab

Warwick University automotive power train laboratory - Microturbine characterisation. The Capstone C30 HEV (Hybrid Electric Vehicle) model microturbine engine installed for use with special active load bank and simulated battery reservoir system. Also for operation on diesel fuel to facilitate exhaust gas emissions testing and evaluation.

ST6L-73 APU running stand and instrumentation

An obsolete but serviceable twin shaft gas turbine engine suitable for education and research purposes. A sophisticated unit originally derived from the World successful PT6 turbo-propeller engine.

More bespoke instrumentation and starting systems for APUs and larger engines