David Budworth and Noel Penny Gas Turbines

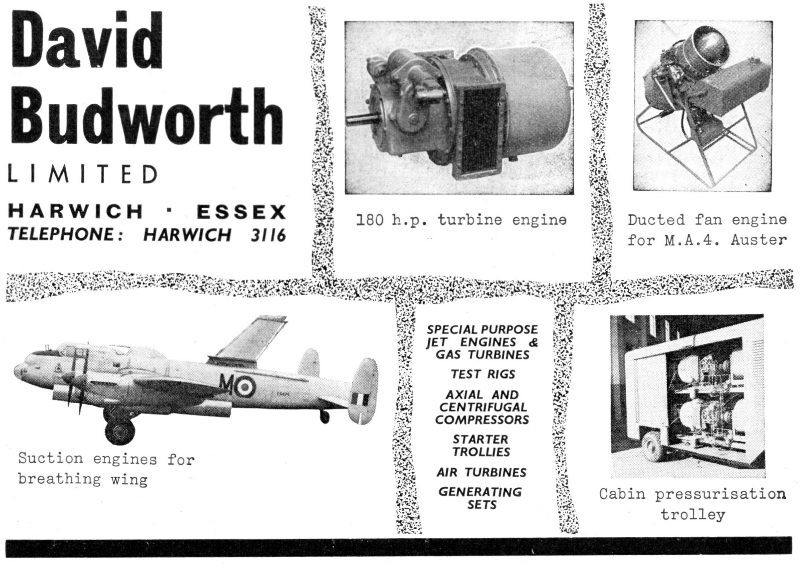

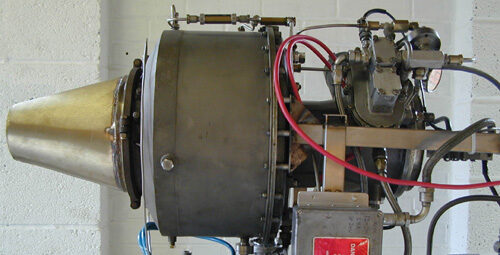

A small company based in Harwich UK was formed by ex Rover Gas Turbines engineer David Budworth and produced a number of small gas turbine engines including turbo-jets and stationary units. Engines were produced in limited numbers including a low-cost industrial gas turbine of 60Hp output and a turbo-jet engine the Budworth Puffin. The puffin engine was adapted for a number of purposes including a two-shaft unit driving an axial compressor. The axial compressor was used to form an Air Supply Unit (ASU). Four off ASUs were fitted to a special heavy-lift road vehicle that had an inflatable hover-craft skirt for use when traversing weak structures and bridges. It was commissioned by an electricity board for the transportation of heavy loads to power stations.

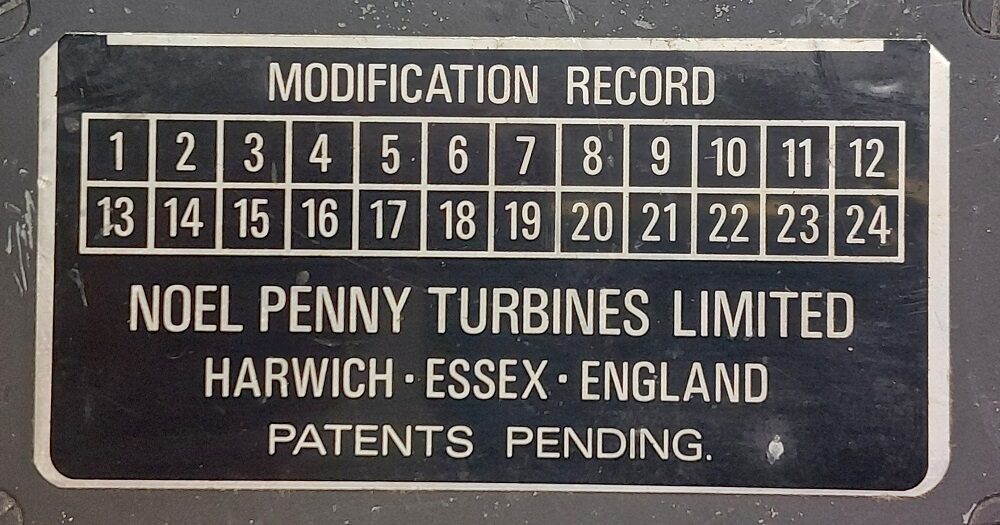

Budworth Turbines was taken over by Noel Penny Turbines in 1975 and the Puffin unit became the NPT100 series. There were issues with early Budworth products concerning quality control and the production of safe homogenous castings for components such as turbine discs.

Budworth units are very rare these days and a few exist in museums. Examples of the NPT100 unit and the stationary engine can occasionally be found.

David Budworth was sadly killed in a flying accident in 1974, like the late Noel Penny, David Budworth may be considered an early pioneer of the British small gas turbine power plant.

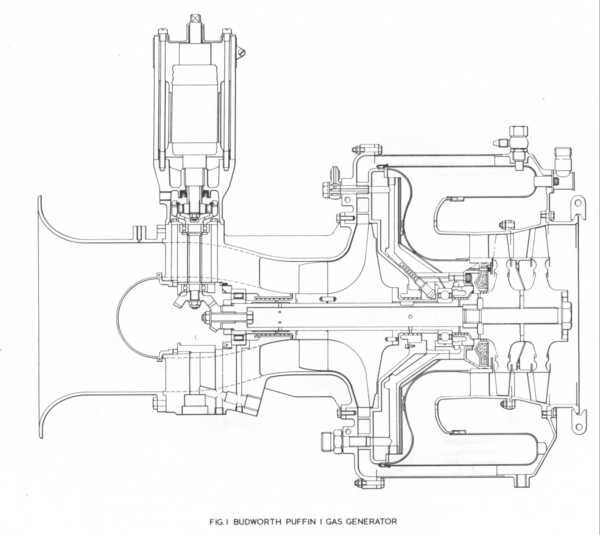

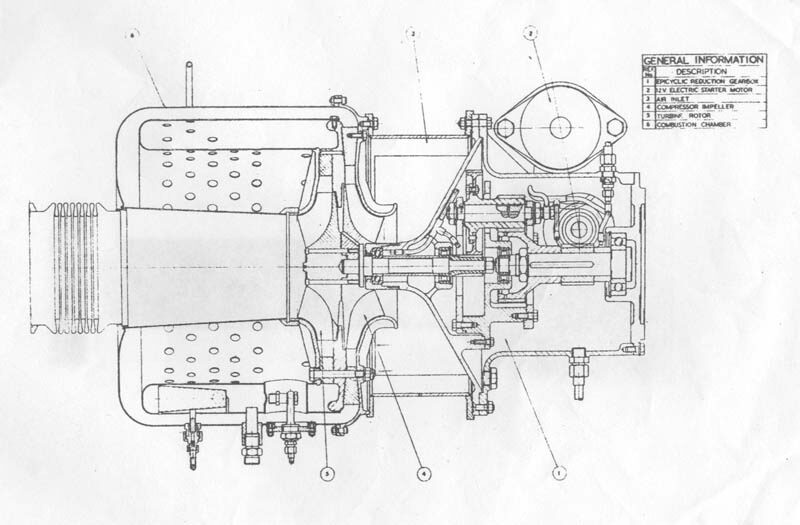

The stationary industrial unit consisted of a simple radial compressor driven by a radial turbine. A surrounding annular combustion chamber was fitted with simple low-pressure vaporizing burners. One version of the engine that was presumably hand-started was fitted with a simple igniter fuse arrangement that had to be lit and placed in the combustor beforehand.

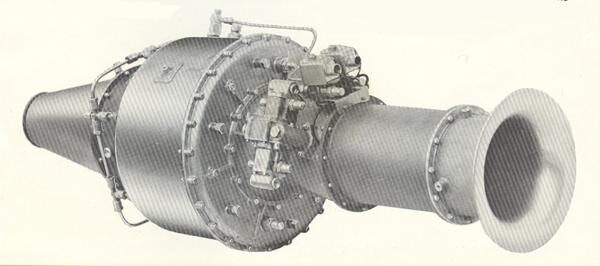

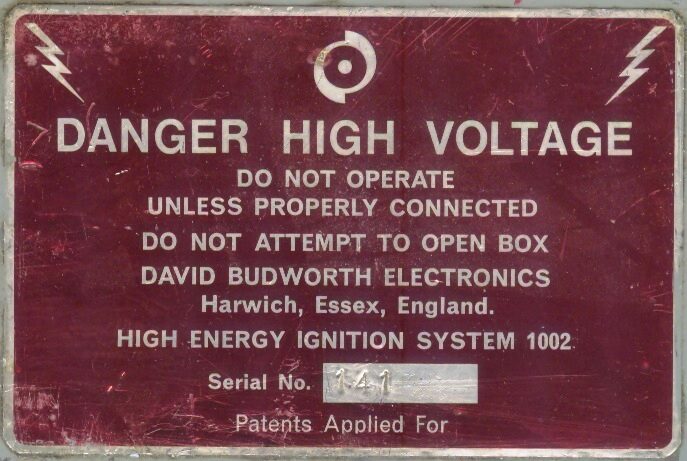

The Puffin unit featured a radial compressor coupled to a two-stage axial turbine. Again, an annular combustion chamber was fitted with vaporizing burners. They were simple bespoke built engines and utilised some components from the automotive industry such as electric pumps and starter motors. Attempts were also made to produce an electronic control system.

Budworth Specification (Estimated)

Power Output................................................................................................50 Bhp

RPM...............................................................................................................40,000

Compressor.............................................................................Centrifugal Impeller

Combustion Chamber.................................Reverse Flow Annular Six Burners?

Turbine................................................................................Radial Inflow Impeller

Layout.......................................................Single Spool with Reduction Gearbox

Starting.........................................................................................................Electric

Ignition................................................................................................High Energy

Fuel System..........................................Gear Pump with Centrifugal Governor?

Lubrication.............................................................................................Dry Sump?

Application................Instructional Engine found in Delf University, Holland

Noel Penny Turbines LTD

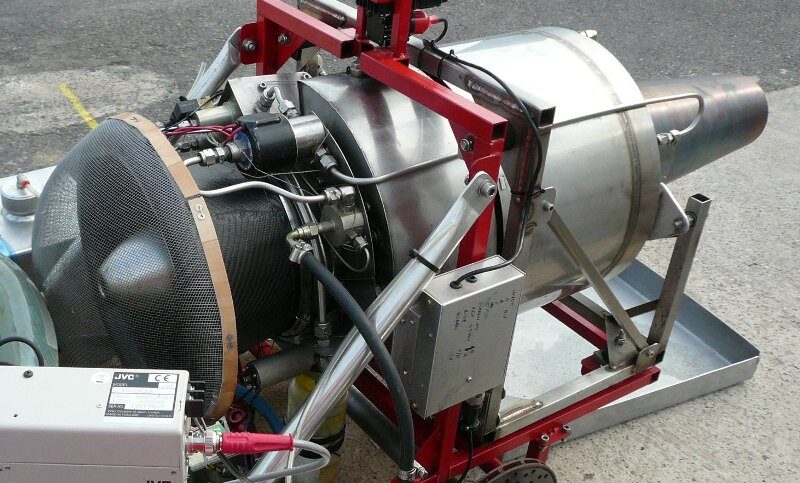

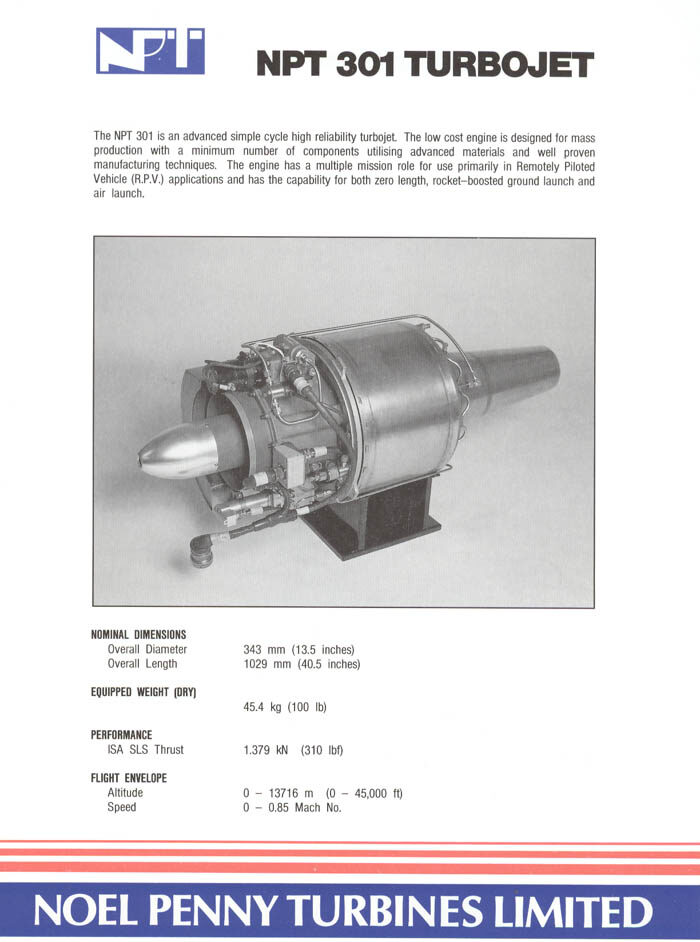

Perhaps one of the UKs most powerful turbojets in its class the Noel Penny Turbines 301 engine was the last design to be produced before the company folded in 1990. This unit bares a number of similarities to its predecessor the similar but much less powerful NPT109. This unit was developed to power recoverable drone type un-manned aircraft and UAVs. Two units were also fitted to the a remarkable prototype four seat bizjet in the late 1980s. A simple but thirsty engine now replaced by much more elaborate units such as the Williams FJX33 turbofan.

NPT Wrote-

The NPT301 is an advanced simple cycle high reliability turbojet. The low cost engine is designed for mass production with a minimum of components utilizing advanced materials and well proven manufacturing techniques. The engine has a multiple mission role for use primarily in Remotely Piloted Vehicle (R.P.V.) applications and has the capability for both zero length, rocket-boosted ground launch and air launch.

The NPT301 turbojet has an annular axial flow intake with three struts supporting the nose bullet which houses a direct driven, self-exciting homopolar alternator. The alternator supplies electrical power of 2.8kw at 28V dc for vehicle use.

The single stage two piece radial compressor discharges via radial diffusers and axial straighteners. The combustion chamber is a single reverse flow type with fuel supplied through twelve vaporizers by an electrically driven fuel pump. Fuel metering is electronically controlled by varying pump speed in accordance with power demand, engine speed and exhaust gas temperature.

The engine can be either air impingement or windmill started with ignition achieved by high energy igniter and pilot atomizer.

The single stage axial turbine with integrally cast disc and blading is directly coupled to the compressor. Similarly, the turbine nozzle has integrally cast nozzle guide vanes and stator diaphragm. The exhaust system consists of an annular diffuser jet pipe with six struts supporting the propelling nozzle.

Two rolling element bearings support he rotor assembly. Each bearing incorporates a squeeze film damper to ensure smooth running of the rotor assembly over the entire operating range. A total loss, pulsed injection oil system is used to supply the squeeze film dampers and to lubricate the engine bearings.

The NPT301 is sea water immersion tolerant and requires only a simple decontamination procedure after immersion.

The engine adopts an almost classic mechanical layout for a small turbojet engine. The NPT301 can be likened to a very large model aircraft powerplant, it is similar mechanically (Although slightly bigger) to the Microturbo TRS18 engine. To keep mechanical complexity down to a minimum, fuel and oil are delivered to the engine by means of electric pumps. The fuel supply is metered to vaporizing burners by varying the pump speed as is the case with later model NPT109s.

A slightly awkward engine to run due to the need for high volume high pressure air for impingement starting. An otherwise straight forward and unsophisticated engine to control provided the necessary electronics can be mastered. The NPT301 would make for a very quick BD5J!

Noel Penny Turbines planned to produce a whole family of small turbojet engines and also a turboshaft unit. Prototype NPT151 and NPT171 units were produced, a very small NPT051, a larger NPT401 and an even an axial flow NPT901 where on the drawing board. Had the company not gone bust, the UK today could have had a very innovative supplier of small gas turbines. Competition from Williams and Microturbo was probably to blame for the down-fall of NPT.

NPT301 Specification

Power Output.............................….…………………………………………………………………….....300 LBs Thrust Static

RPM...........................….…………………….....…………………......................40,500 rpm (100%), Idle 26,000 rpm

Compressor..................….…………………....………………………….....................Single Stage Centrifugal Impeller

Air Mass Flow..............….……………………...…………………………………………………………………....................2.27 kg/s

Pressure Ratio.....................….…………….....………………………………………………………………………………….............4.7

Combustion Chamber.....….………………………….................Reverse Flow Annular with Vaporizing Burners.

Turbine..............................….…………….........……………………………………………................Axial Flow Single Stage

Layout...............................….…………….........………………………................Single Spool Classic Simple Turbojet

Starting................................….…………......…………………………………………………………….............Air Impingement

Ignition........................….……………….......………………….....................Torch Igniter with High Energy Exciter

Fuel System.............................…...............Electric Motor Driven Metering Pump and Scheduling Valves

Lubrication...........................….…......……………............Total Loss, Pulsed Electric Pump, Integral Oil Tank

Oil Spec...............................….…....……………………………………………………............Aeroshell 750 MIL-L-23699

Accessories...............................................Engine Speed 2.5Kw Brushless Homopolar Alternator in Nose

Weight...............................…........…………………………………………………………………………………………...............45 kg

Application....….…………........Various Target Drones, 301-3/4 in Prototype CMC Leopard Jet, Go-Kart

Fuel Consumption.....…...…………………………………………………………………………........................1.08 Lbs/h/lb st.

Dimensions.............….……........…………………………………………………...........................39.6" x 13.5" Inc Jet Pipe

A very good read; The history of Noel Penny’s life and his work at Rover, NPT and Williams. Published by John Mortimer