IHI Dynajet 2.6 Portable Microturbine Generator

An astonishing piece of Japanese engineering, a 2.6Kw alternator driven by a tiny gas turbine. A profound technical achievement, no other company in the World has produced anything like it. A simple to operate recuperated generator completely self contained, silenced and able to run for up to an hour on the on-board fuel tank. An on-board Ni-Cad battery provides starting power, neat access flaps and hatches provide access to routine service components. A typical Japanese quality, well thought out product that was beautifully engineered.

No longer in production but IHI continue to develop other small gas turbines experimentally but sadly not in volume manufacture.

Probably the World’s least powerfully rated turbo-shaft gas turbine engine ever produced!

More on the Dynajet development - White Paper

In 2002:-

“IHI to launch portable microturbine generator”

“4 October 2002 - Japan's Ishikawajima-Harima Heavy Industries Co. (IHI) says it will next month begin marketing a portable gas turbine generator so small it can be carried by two people.

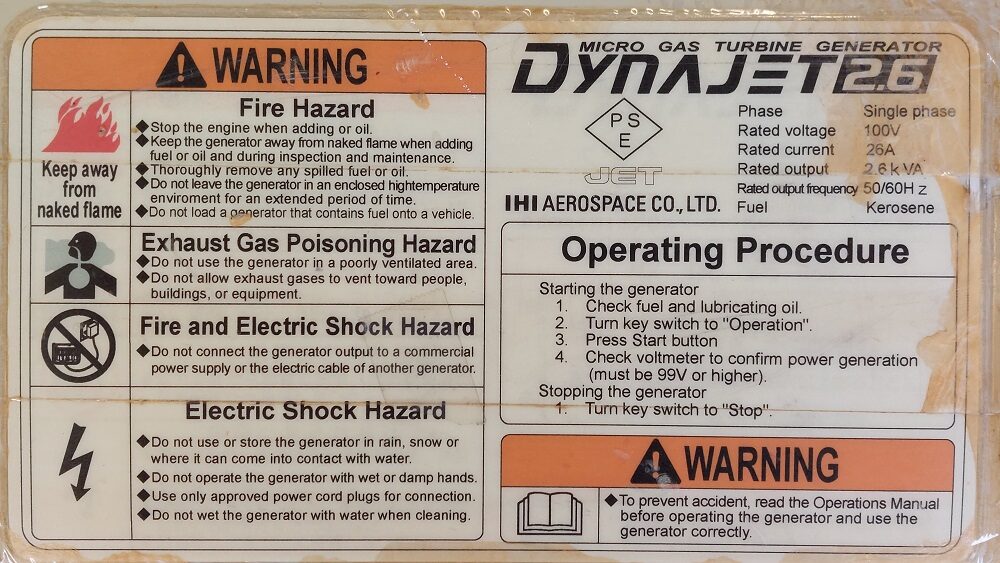

The new Dynajet 2.6 gas microturbine generator, developed by subsidiary IHI Aerospace Co., burns kerosene to rotate a turbine and generate 2.6kw of power -- enough electricity to meet the power needs of a single household. It is the size of the outside unit of a typical home air conditioner and weighs 67kg.

Priced around 1m yen ($8156), the Dynajet 2.6 is several times costlier than a gasoline-engine-based power generator of comparable output but operates with far less burden on the environment, releasing one-seventh the nitrogen oxides and 1/60 the carbon monoxide. It also vibrates less and operates more quietly.

IHI will market the new gas microturbine generator for use at residential construction sites and event sites.”

Dynajet 2.6 Specification

Power output....................…...................................................................................2.6Kw

Voltage and Frequency…………………………………………………………….110V 50/60Hz

RPM...................................................................................................................100,000

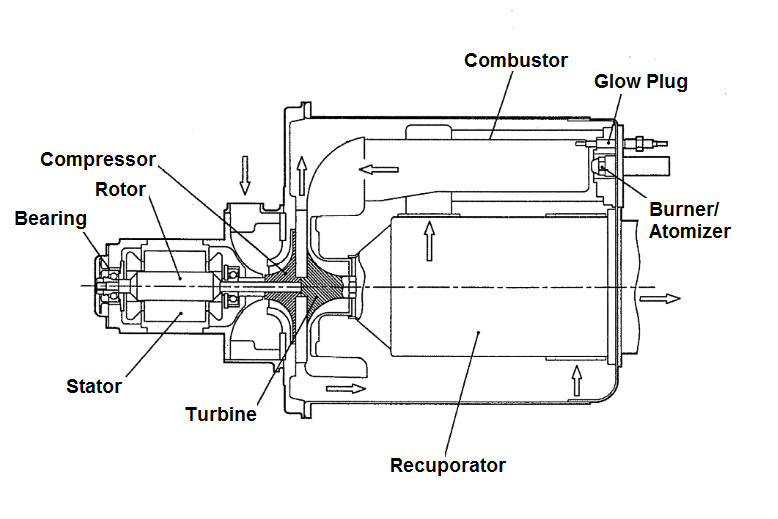

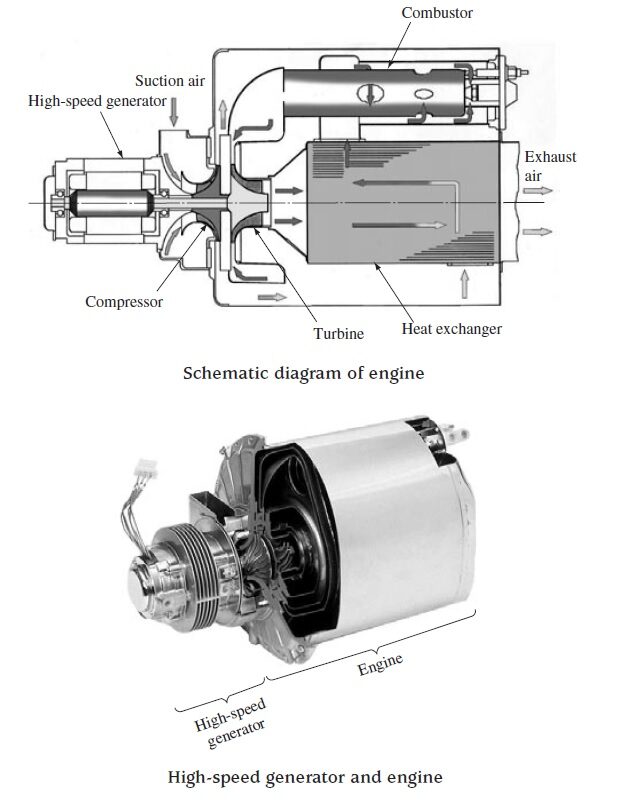

Compressor..................….……..…...................................................centrifugal Impeller

Turbine..........................................….….........................................................radial inflow

Combustor...........….…….................................................single can type with atomizer

Layout.....……..single spool direct drive with static recuperator (heat exchanger)

Starting.................….…........................................................................starter generator

Ignition..............................................................................................................glow plug

Fuel system.........................….……...................................Liquid fuel (kerosene Jet A1)

Lubrication.....................…...........re-circulating pressure oil system, integral sump

Accessories.......................….…......................................permanent magnet generator

Control system...............….……...…...................................electronic microprocessor

Applications....................….…..............….……...............standby power for IT systems